-

Bastidor de la aleación de aluminio

-

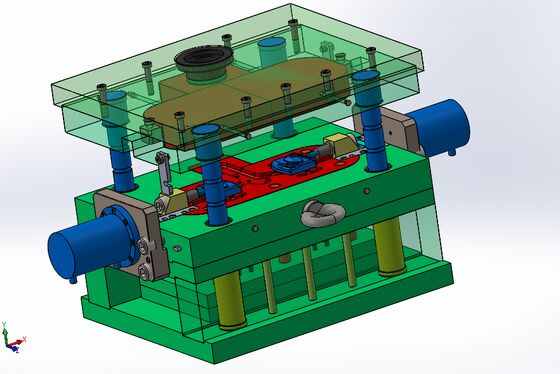

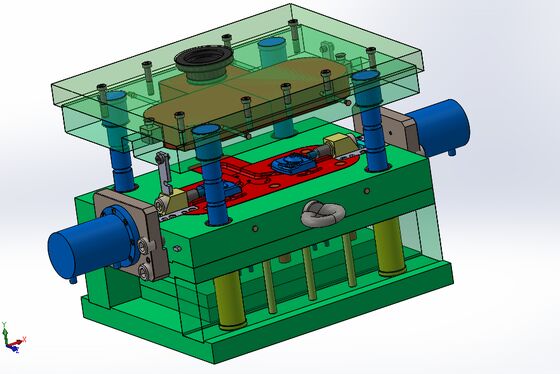

La presión a presión molde de la fundición

-

moldes de fundición de metales

-

De aluminio de fundición del molde

-

Molde de la espuma del EPS

-

Molde perdido de la espuma

-

Molde de bastidor de arena

-

aluminio de fundición de moldes permanentes

-

De aluminio de fundición por gravedad morir

-

Mueren los útiles de la fundición de aluminio

-

Molde de las piezas de automóvil

-

Molde multi cavidad

-

Molde de culata

-

molde de la alta precisión

-

Servicio de impresión rápido 3d

-

Greg HenkGracias por su hospitalidad bondadosa. Su compañía es muy profesional, nosotros tendrá cooperación agradable en un futuro próximo.

Greg HenkGracias por su hospitalidad bondadosa. Su compañía es muy profesional, nosotros tendrá cooperación agradable en un futuro próximo. -

Lobo de LionelBuena compañía con servicio agradable y la reputación de alta calidad y alta. Uno de nuestro proveedor confiable, las mercancías se entrega a tiempo y paquete agradable.

Lobo de LionelBuena compañía con servicio agradable y la reputación de alta calidad y alta. Uno de nuestro proveedor confiable, las mercancías se entrega a tiempo y paquete agradable.

Fabricante de moldes de inyección de plástico PVC para moldes de lámparas/piezas automotrices, moldes de piezas de automóviles de aluminio de alta calidad

Póngase en contacto conmigo para muestras y cupones gratis.

WhatsApp:0086 18588475571

- ¿ Qué es eso?: 0086 18588475571

¿ Qué pasa?: sales10@aixton.com

Si usted tiene alguna preocupación, proporcionamos ayuda en línea de 24 horas.

x| Nombre | Molde de inyección de plástico | Vida del molde | >1.000.000 tiros |

|---|---|---|---|

| Tratamiento superficial | Tratamiento térmico | Gama de productos | Molde de piezas para automóviles |

| espesor medio de la pared | > 3 mm | Función | Anti corrosión |

| Resaltar | Molde de inyección de PVC para piezas automotrices,Molde de piezas de automóviles de aluminio,Molde de inyección para lámparas automotrices |

||

Fabricante de moldes de plástico de inyección de PVC para piezas de lámparas de automóviles

Dedicados a la excelencia en herramientas de automóviles, fabricamos moldes de piezas de automóviles de precisión que encarnan durabilidad, precisión y sofisticación tecnológica.Nuestros moldes no son simplemente herramientas de producciónEn la actualidad, la industria automotriz se ha convertido en un sector de la industria automotriz en el que la mayoría de las empresas se han dedicado a la fabricación de automóviles.trabajar de forma transparente para traducir las especificaciones de su pieza en un molde que ofrezca calidad y fiabilidad sin concesiones durante toda su vida útil.

Características

-

Análisis riguroso de elementos finitos (FEA):La estructura del molde se somete a una simulación exhaustiva de FEA para predecir y prevenir la desviación bajo altas presiones de inyección, garantizando la estabilidad dimensional de las piezas producidas a largo plazo.

-

Especificaciones de resistencia a la corrosión:Para las piezas que utilizan resinas abrasivas o corrosivas (por ejemplo, materiales llenos), especificamos y tratamos los aceros en consecuencia,y puede incorporar componentes de acero inoxidable en áreas críticas para evitar la degradación y la mancha.

-

Seguridad y funcionamiento centrados en el usuario:Incluye características de seguridad como bloqueos, mecanismos de seguridad contra caídas y marcas de identificación claras para promover la instalación y operación seguras en un entorno de producción acelerado.

-

Sistemas de corriente de alto flujo:Implementa sistemas de corriente caliente o diseños de corriente fría optimizados para reducir el desperdicio de material, mejorar el equilibrio de llenado y permitir una producción totalmente automatizada y sin sprue.

Especificación

|

Nombre del producto

|

Molde de piezas de automóvil

|

||

|

Tamaño

|

Personalizado

|

||

|

El color

|

Como sus requisitos

|

||

|

El material

|

Aluminio, Metal, según sus requisitos

|

||

|

Aplicación

|

Partes de automóviles, luminarias, cubiertas de lámparas, carcasas de luces de led, disipadores de calor o cualquier otro tipo de piezas de fundición a presión

|

||

|

Servicio

|

Producción de equipos OEM/ODM

|

||

|

Diseño del producto

|

Personalizada según los dibujos o muestras del cliente

|

||

Nuestra fábrica

Bienvenido a visitar nuestra fábrica, siempre damos la bienvenida a su llegada

![]()

![]()

![]()

![]()

Proceso de fabricación

1Revisar el diseño de la pieza, los dibujos y el estándar de calidad de los clientes.

2Diseño y fabricación de moldes y herramientas

3Prueba de molde y herramienta y confirmación de la muestra

4. Dibujo de piezas de fundición en bruto

5Tratamiento de superficie: recorte, desborda, pulido, limpieza, pasivación y recubrimiento de potencia y otros requisitos del cliente

6Mecanizado de precisión: tornos CNC, fresado, perforación, molienda, etc.

7Inspección completa.

8Envasado.

9Entrega.

![]()

Aplicación

Adecuado para la fabricación de una amplia gama de componentes técnicos y estéticos de automóviles, incluidas piezas críticas relacionadas con la seguridad, como biseles para grupos de instrumentos,con un diámetro superior a 30 mm,, y componentes para sistemas de frenos o de combustible; así como partes grandes y complejas como paneles de puertas, puertas traseras y spoilers que requieren ajuste y acabado precisos.Nuestras herramientas apoyan la producción de piezas utilizando plásticos de ingeniería, compuestos y polímeros estándar de grado automotriz.

Nuestras ventajas

1Somos uno de los más grandes fabricantes de molde de espuma perdida en China, nos centramos en el molde de espuma perdida de alto desafío y tenemos grandes centros de mecanizado de pórtico,30 juegos de centro de mecanizado de alta velocidad importados, más de 40 juegos de máquinas herramienta generales;

2Tenemos 36 diseñadores de moldes de alto nivel, para garantizar un diseño de moldes razonable / seguridad / alta eficiencia y garantizar la entrega rápida de moldes y la estructura racional del molde,hacer el proceso más seguro y la eficiencia de producción más alta;

3Utilizamos una máquina de control numérico para fabricar las cavidades del molde, para asegurar un espesor uniforme.

4Usamos ZL104 Aluminio para moldear el molde, para fabricar un molde de alta resistencia;

5Para el molde grande, utilizamos Ø22*1 tubo de cobre como tubo de enfriamiento, con sistema de rociado de agua, para obtener un buen efecto de enfriamiento;

6Tenemos (TEF10N) recubrimiento en la superficie del molde, puede reducir la fricción, anti agua / electricidad estática / ácido-base / alta temperatura,Con esto podemos asegurar que el patrón tiene una superficie lisa sin distorsión, y fácil de desmoldear;

7Todos los tornillos que utilizamos son de acero inoxidable, fácil de desmontar durante el mantenimiento;

8Para la caja de molde grande, utilizamos una placa de aluminio forjado de 18-20 mm de espesor, para ofrecer una cavidad de alta resistencia;

9Para el molde complejo que es difícil de desmoldear, podemos fabricar el molde automático con dispositivo de extracción.

10Producimos la muestra del patrón al cliente después de terminar el molde, cuando el patrón fue calificado, entonces hacemos el trabajo de excepción para el molde;

11Tenemos el instrumento de medición de coordenadas hexagonales importado de Suiza para hacer una prueba asegurarse de que nuestro molde calificado.

Perfil de la empresa

Luoyang Liushi molde Co., Ltd se estableció en 2001, que es la Unidad Nacional de Establecimiento de Estándares para el Molde de Fusión de Espuma Perdida.ciudad de la flor de peonía de la ciudad de LuoyangTenemos 9800 edificios de oficinas y 22000 talleres, que están bien equipados con investigación, desarrollo, diseño, fundición, mecanizado, montaje, tratamiento de superficie y otros equipos.Es un centro de investigación y desarrollo y centro tecnológico de Luoyang..

![]()

Los técnicos de la empresa pueden proporcionar el ensamblaje del molde guía en el sitio, la producción de prueba, la reparación gratuita y la tecnología completa para los procesos de fundición de espuma perdida de acuerdo con las demandas del cliente.Con la filosofía de negocio de "diseño cuidadoso", fabricación delgada, mejor servicio, calidad perfecta", nos esforzamos por proporcionar productos y servicios satisfactorios para los clientes.Nuestra empresa se ha convertido en el proveedor preferido de moldes de muchos fabricantes de fundición de espuma perdida y el proveedor exclusivo.

¿Por qué elegirnos?

- Sistema de gestión de la calidad certificado: Nuestras operaciones se rigen por un sistema de gestión de la calidad certificado ISO 9001, que proporciona un marco estructurado para la coherencia, la trazabilidad,y la mejora continua en cada proyecto que emprendemos.

- Control de fabricación interno: al mantener los procesos de mecanizado básicos en casa, garantizamos un control de calidad superior, protegemos su propiedad intelectual y mantenemos la flexibilidad,programación receptiva durante todo el proceso de construcción.

- Gestión de proyectos dedicada: a cada cliente se le asigna un gerente de proyecto dedicado que sirve como su único punto de contacto, asegurando una comunicación clara, actualizaciones oportunas,y resolución eficiente de cualquier consulta desde el inicio hasta la entrega.

- Experiencia probada con clientes globales: Nuestra cartera incluye asociaciones exitosas y a largo plazo con proveedores de automóviles de toda Europa, América del Norte y Asia,Demostrando nuestra capacidad para cumplir con diversos estándares y expectativas internacionales.