-

Bastidor de la aleación de aluminio

-

La presión a presión molde de la fundición

-

moldes de fundición de metales

-

De aluminio de fundición del molde

-

Molde de la espuma del EPS

-

Molde perdido de la espuma

-

Molde de bastidor de arena

-

aluminio de fundición de moldes permanentes

-

De aluminio de fundición por gravedad morir

-

Mueren los útiles de la fundición de aluminio

-

Molde de las piezas de automóvil

-

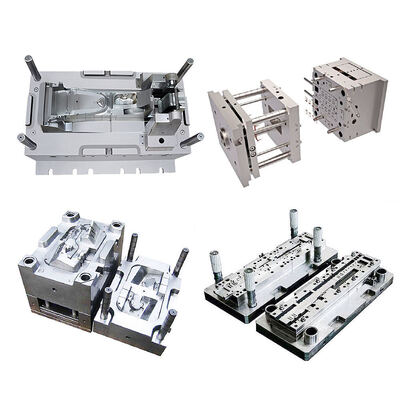

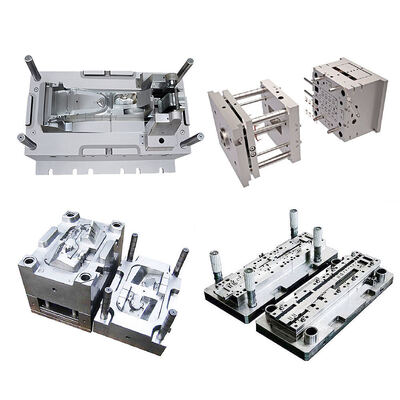

Molde multi cavidad

-

Molde de culata

-

molde de la alta precisión

-

Servicio de impresión rápido 3d

-

Greg HenkGracias por su hospitalidad bondadosa. Su compañía es muy profesional, nosotros tendrá cooperación agradable en un futuro próximo.

Greg HenkGracias por su hospitalidad bondadosa. Su compañía es muy profesional, nosotros tendrá cooperación agradable en un futuro próximo. -

Lobo de LionelBuena compañía con servicio agradable y la reputación de alta calidad y alta. Uno de nuestro proveedor confiable, las mercancías se entrega a tiempo y paquete agradable.

Lobo de LionelBuena compañía con servicio agradable y la reputación de alta calidad y alta. Uno de nuestro proveedor confiable, las mercancías se entrega a tiempo y paquete agradable.

Moldeo de plástico ABS para piezas electrónicas automotrices de precisión, fabricación de moldes personalizados, fabricación de moldeo por inyección

Póngase en contacto conmigo para muestras y cupones gratis.

WhatsApp:0086 18588475571

- ¿ Qué es eso?: 0086 18588475571

¿ Qué pasa?: sales10@aixton.com

Si usted tiene alguna preocupación, proporcionamos ayuda en línea de 24 horas.

x| Nombre | Molde de inyección de plástico | Vida del molde | >1.000.000 tiros |

|---|---|---|---|

| Tratamiento superficial | Tratamiento térmico | Gama de productos | Molde de piezas para automóviles |

| espesor medio de la pared | > 3 mm | Función | Anti corrosión |

| Resaltar | Molde automotriz de plástico ABS,Moldeo por inyección personalizado de piezas de automóviles,Molde ABS electrónico de precisión |

||

Fabricación de moldes de plástico para piezas electrónicas automotrices de precisión, fabricación de moldes personalizados por inyección

Entregamos moldes de piezas automotrices críticos para la misión, diseñados para las rigurosas exigencias de los componentes automotrices estructurales y semiestructurales. Nuestra experiencia radica en la creación de sistemas de herramientas robustos que producen constantemente piezas con una integridad mecánica excepcional, tolerancias ajustadas y un rendimiento fiable bajo estrés. Entendemos que estos componentes son integrales para la seguridad y el funcionamiento del vehículo, y nuestros moldes están diseñados en consecuencia, utilizando principios de ingeniería avanzados para garantizar una producción impecable de geometrías complejas y de alta resistencia que cumplen con los protocolos de prueba más estrictos de la industria automotriz.

Características

- Diseño de compatibilidad de alto tonelaje: Diseñado con pilares de soporte reforzados, placas de alta resistencia y enclavamientos estratégicamente ubicados para soportar fuerzas de sujeción excepcionalmente altas sin deflexión, lo que garantiza la consistencia de las piezas en aplicaciones grandes o de embutición profunda.

- Ventilación superior para geometrías complejas: Implementa un sistema de ventilación avanzado de múltiples etapas, que incluye ventilaciones perimetrales y canales de vacío dedicados, para eliminar las trampas de aire en costillas intrincadas, resaltes y huecos profundos, evitando quemaduras y llenado incompleto.

- Ingeniería de superficie duradera para materiales abrasivos: Cavidades y núcleos especialmente tratados con mayor dureza superficial (por ejemplo, mediante recubrimientos especializados o doble templado) para resistir el desgaste de plásticos de ingeniería abrasivos con relleno de vidrio, relleno de minerales u otros comunes en aplicaciones bajo el capó y en el chasis.

- Preparación integrada para sensores: Diseñado con provisiones para instalar sensores de presión, temperatura y cavidad, lo que permite el monitoreo del proceso en tiempo real y facilita el control de calidad basado en datos y estrategias de mantenimiento predictivo.

Especificación

Nombre del producto | Molde de piezas de automóviles | ||

Tamaño | Personalizado | ||

Color | Según sus requisitos | ||

Material | Aluminio, Metal, Según sus requisitos | ||

Aplicación | Piezas de automóviles, accesorios de iluminación, cubierta de lámpara, carcasa de luz led, disipador de calor o cualquier otro tipo de piezas de fundición a presión | ||

Servicio | OEM/ODM | ||

Diseño del producto | Personalizado según los dibujos o muestras de los clientes | ||

Nuestra fábrica

Bienvenido a visitar nuestra fábrica, siempre agradecemos su llegada

![]()

![]()

![]()

![]()

Proceso de fabricación

1. Revisar el diseño de la pieza, los dibujos y el estándar de calidad de los clientes.

2. Diseño y fabricación de moldes y herramientas

3. Prueba de moldes y herramientas y confirmación de la muestra

4. Fundición en bruto a presión

5. Tratamiento de la superficie: Recorte, desbarbado, pulido, limpieza, pasivación y recubrimiento en polvo y otros requisitos del cliente

6. Mecanizado de precisión: Tornos CNC, fresado, taladrado, rectificado, etc.

7. Inspección completa

8. Embalaje

9. Entrega

![]()

Aplicación

Adecuado para la fabricación de una amplia gama de componentes automotrices técnicos y estéticos. Esto incluye piezas críticas relacionadas con la seguridad, como biseles para grupos de instrumentos, cuerpos de conectores para mazos de cables y componentes para sistemas de frenado o combustible; así como piezas grandes y complejas como paneles de puertas, portones traseros y alerones que requieren un ajuste y acabado precisos. Nuestras herramientas admiten la producción de piezas utilizando plásticos de ingeniería, compuestos y polímeros de grado automotriz estándar.

Nuestras ventajas

1. Somos uno de los mayores fabricantes de moldes de espuma perdida en China, nos enfocamos en moldes de espuma perdida de alto desafío y tenemos grandes centros de mecanizado de pórtico, 30 juegos de centros de mecanizado de alta velocidad importados, más de 40 juegos de equipos de herramientas de máquina en general;

2. Contamos con 36 diseñadores de moldes senior, para garantizar un diseño de moldes razonable / seguro / de alta eficiencia y garantizar la entrega rápida de moldes y una estructura de moldes racional, hacer que el proceso sea más seguro y la eficiencia de producción más alta;

3. Utilizamos herramientas de máquina de control numérico para fabricar las cavidades del molde, para garantizar un grosor uniforme;

4. Utilizamos aluminio ZL104 para fundir el molde, para fabricar un molde de alta resistencia;

5. Para el molde grande, utilizamos un tubo de cobre Ø22*1 como tubería de enfriamiento, con sistema de rociado de agua, para obtener un buen efecto de enfriamiento;

6. Tenemos recubrimiento (TEF10N) en la superficie del molde, puede reducir la fricción, anti agua / electricidad estática / ácido-base / alta temperatura, con esto podemos garantizar que el patrón tenga una superficie lisa sin distorsión y sea fácil de desmoldar;

7. Todos los tornillos que utilizamos son tornillos de acero inoxidable, fáciles de desmontar durante el mantenimiento;

8. Para el cofre del molde grande, utilizamos una placa de aluminio forjado de 18-20 mm de espesor, para ofrecer una cavidad de alta resistencia;

9. Para el molde complejo que es difícil de desmoldar, podemos fabricar el molde automático con dispositivo de extracción;

10. Producimos la muestra del patrón al cliente después de terminar el molde, cuando el patrón está calificado, entonces hacemos el trabajo de aceptación para el molde;

11. Tenemos el instrumento de medición de coordenadas Hexagon importado de Suiza para realizar una prueba y asegurarnos de que nuestro molde esté calificado.

Perfil de la empresa

Luoyang Liushi mould Co., Ltd se estableció en 2001, que es la Unidad de Establecimiento de Estándares Nacionales para el Molde de Fundición de Espuma Perdida. La empresa está ubicada en la Ciudad del Milenio Emperador, ciudad de la flor de peonía de la ciudad de Luoyang. Tenemos un edificio de oficinas de 9800 y un taller de 22000, que está bien equipado con investigación, desarrollo, diseño, fundición, mecanizado, montaje, tratamiento de superficies y otros equipos. Es un centro de I+D y centro tecnológico municipal de Luoyang.

![]()

Los técnicos de la empresa pueden proporcionar montaje de moldes, producción de pruebas, reparación gratuita y tecnología completa in situ para el proceso de fundición de espuma perdida de acuerdo con las demandas del cliente. Con la filosofía empresarial de "diseño cuidadoso, fabricación ajustada, el mejor servicio, calidad perfecta", nos esforzamos por proporcionar productos y servicios satisfactorios a los clientes. Después de años de desarrollo, nuestra empresa se ha convertido en el proveedor de moldes preferido de muchos fabricantes de fundición de espuma perdida y el proveedor exclusivo.

Por qué elegirnos

Especialización en plásticos de ingeniería: Nuestro equipo tiene una profunda experiencia en el procesamiento de una amplia gama de polímeros de alto rendimiento (PPA, PBT, PPS, etc.), lo que nos permite diseñar moldes que gestionan de forma óptima sus características únicas de flujo, enfriamiento y contracción.

Proceso de desarrollo con mitigación de riesgos: Empleamos un proceso de puerta escalonado con hitos claros para la revisión del diseño, la aprobación de la muestra y las pruebas previas al envío, minimizando el riesgo del proyecto y garantizando la alineación con sus especificaciones técnicas en cada paso.

Optimización del costo del ciclo de vida: Nuestra filosofía de diseño se centra en el costo total de propiedad, equilibrando la inversión inicial con factores como la frecuencia de mantenimiento, el consumo de energía (a través de un enfriamiento eficiente) y la longevidad de los componentes para ofrecer el mejor valor a largo plazo.

Coordinación de la red de servicio global: Hemos establecido asociaciones con proveedores de servicios técnicos de confianza en las principales regiones automotrices, lo que garantiza que pueda acceder al soporte local calificado para el mantenimiento y la solución de problemas si es necesario.